Injection moulding of technical parts

An injection moulding workshop 4.0 at the heart of technological developments…from idea to technicity.

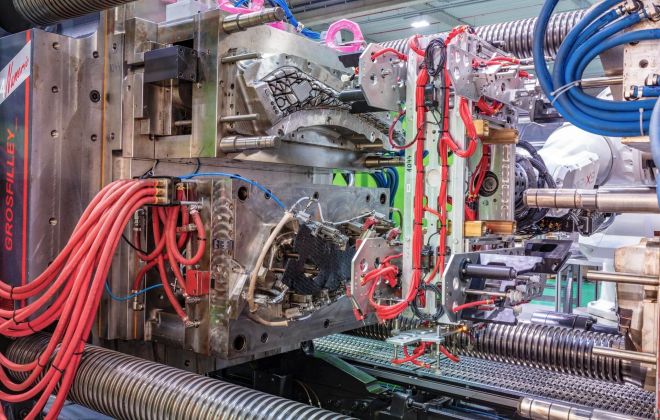

Our workshop combines the latest generation of injection moulding machines, advanced technology in bi- and tri-material injection moulding and hybrid injection moulding, innovative automatic in-mold assembly process and a high production rate.

Regarded as the technical and technological heart of the injection moulding of precise parts, our workshop is equipped with a modern machine park enabling us to carry out advanced and innovative processes.

In our quest for continuous improvement, we have developed a unique process for thermoforming and overmoulding, in a single operation, a composite sheet (Organosheet), incorporating an insert overmoulding, providing a high degree of functionalisation and great repeatability.

We add a technical dimension to the parts through various processes such as PUR sealing, overmoulding of metal inserts, ferrite magnetisation and automatic in-mold assembly.

Our machine park is equipped with bi and tri-material injection moulding machines, allowing us to achieve savings in cycle time and tooling costs. At EMI, we also master the MuCell technology used for thin-walled parts. This technology allows significant reductions in costs, weight and defects of thermoplastic parts. We can also respond to mass production demands by using cube moulds to inject 128 cavities simultaneously, while the other 128 cavities are unscrewed by an automatic unscrewing peripheral device.

Using the right technology in the right place to optimise manufacturing costs is the guiding principle at EMI.

- Part accuracy +/- 5/100th

- Bi and tri-material injection moulding

- MuCell technology

- Hybrid injection moulding process for composites (Organosheet)

- Mass production with cube moulds

- Overmoulding/Magnetisation/PUR seal/Automatic assembly/Laser marking