Renewable energies

Inexhaustible sources of energy, renewable energies represent one of the fastest growing sectors requiring technical thermoplastic parts in very large series.

The parts designed for equipment in this field must meet requirements in terms of precision, repeatability, quantity and lifetime. Thanks to its large and constantly renewed machine park, its multi-cavity tooling and the use of technical materials, EMI provides a high-performance response adapted to this demanding sector.

CUSTOMER CASE STUDY

Our customer is a global supplier of mechatronic solutions offering a wide range of products for connection and robotic system.

01 CHALLENGE

In order to develop its set of technical parts, our customer needed an injection mould maker capable of developing and producing these parts in very large quantities. Additional criteria concerning the repeatability and accuracy of the products also had to be taken into account in order to guarantee the compatibility of the parts between them, despite the production of the same reference on several identical tools.

The use of a UL-approved thermoplastic material, which meets strict standards for outdoor use of the finished parts, also led to additional processing challenges.

02 APPROACH & SOLUTION

The project began with the development of a part design compatible with the needs of thermoplastic injection moulding. Then test moulds and prototype tools were developed to validate the various characteristics of the parts. Then several multi-cavity steel tools, some of which were bi-material, were designed internally, in order to produce the different parts made of different materials constituting the finished product.

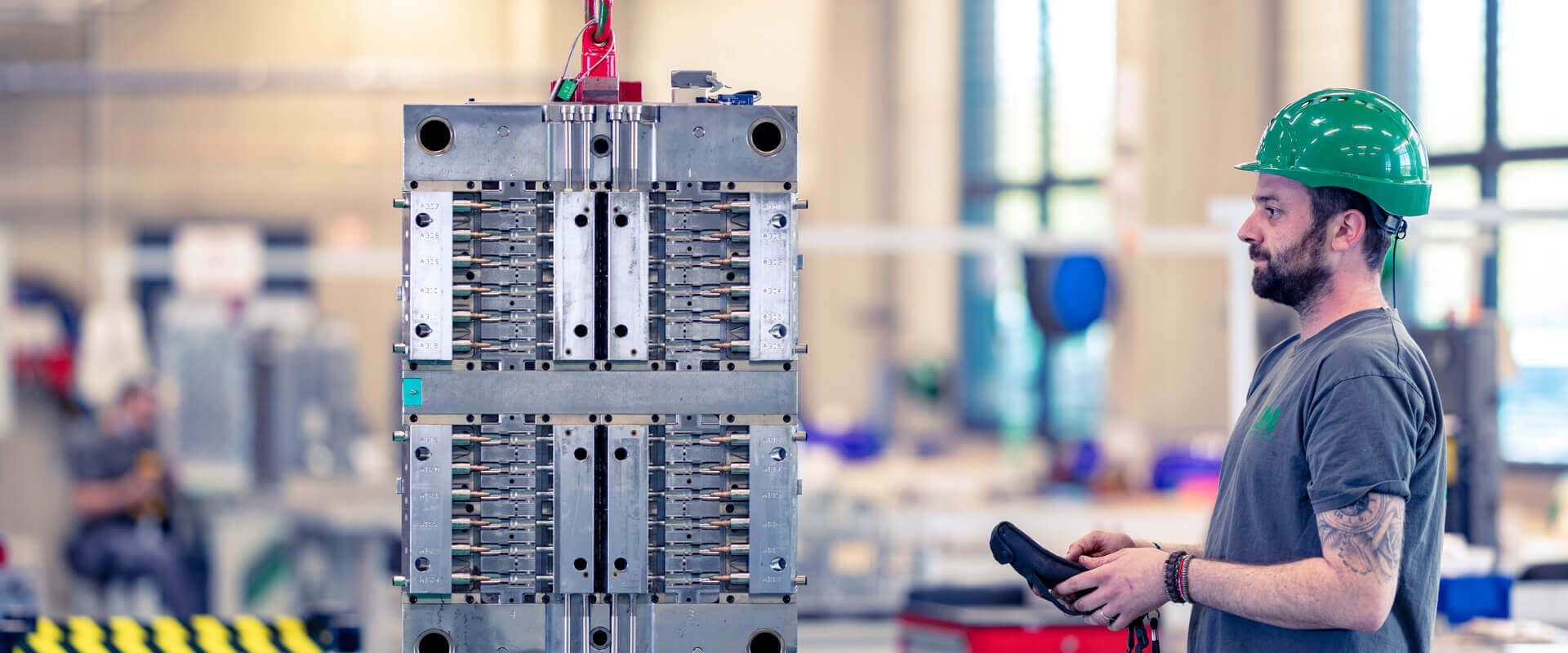

Cube moulds, mounted on two injection moulding machines, were developed for this product, allowing 128 cavities to be moulded in masked time while the other 128 cavities were unscrewed, in a single injection moulding cycle.

In order to ensure optimal quality, a 100% camera control was integrated into the process to guarantee the watertightness of the assembly. A customisation stage using inkjet marking and long-lasting tampoprinting was also applied to the product. To finalise the sub-assembly, the assembly of the various components, including metal inserts and O-rings, was then automated in order to reduce intermediate steps and thus optimise costs.

- 100 t and 320t injection moulding machines

- 128-cavity cube tools

- 80-cavity bi-material tools

- Injection moulding and unscrewing in the tooling within one injection cycle

- 100% camera control

- Inket and padprinting

- Automated assembly

- Inflow moisture conditionning