Electrical & Connections

Now omnipresent, these two constantly evolving sectors are faced with permanent challenges of standardization, power or functionality of the devices they connect.

By co-developing the parts, EMI participates in the challenge taken up by the key-players in the sector by providing, for example, overmoulding or bi/tri-material injection moulding solutions and by complying with the certifications that are essential for the safety of the parts, such as UL certification (fire protection).

CUSTOMER CASE STUDY

Our customer is a company specialised in products and solutions for building control and technical management.

01 CHALLENGE

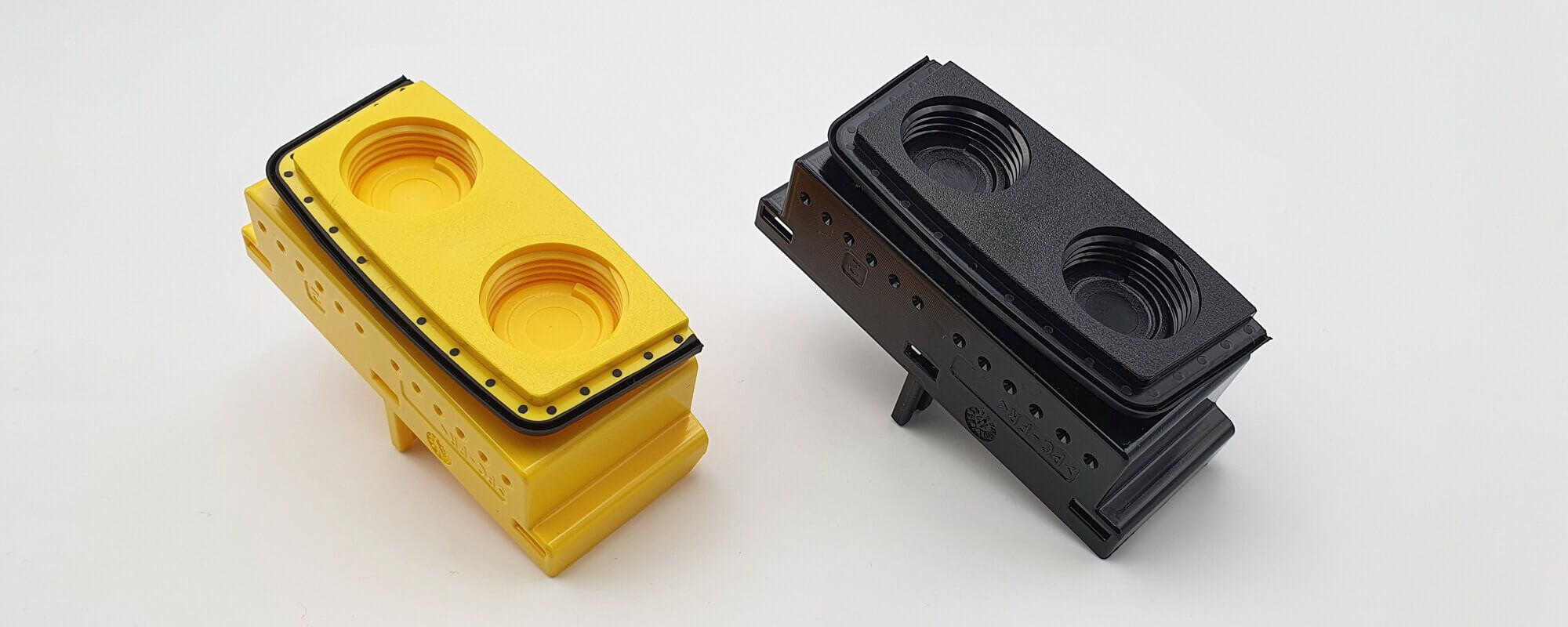

To design its product, our customer was looking for an injection mould maker capable of producing a leak-proof bi-material part, including two threaded holes leading to a breakaway part. Because of its function as an electrical cable connector, the part had to be made of a material that was suitable for fire protection and had to meet precision requirements for the passage of wires.

02 APPROACH & SOLUTION

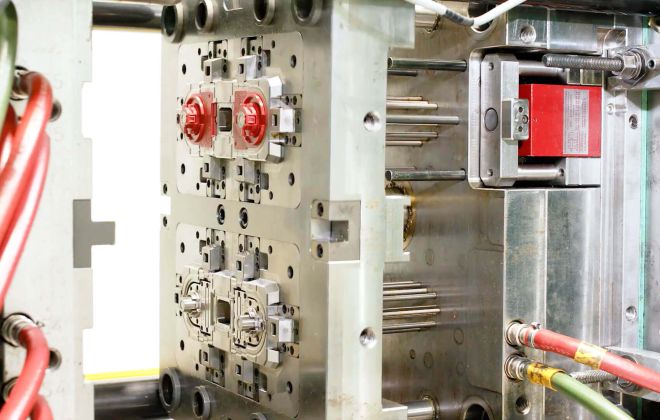

The bi-material dual cavity tooling used for this part was developed in-house and includes a second version. A rack and pinion gear driven by a cylinder was added to unscrew the two threaded holes.

In order to guarantee the watertightness of the part, a seal was overmoulded, the strength of which was consolidated by chemical adhesion and reinforced by a mechanical bonding. Risers were added to ensure the complete filling of the functional part.

Thanks to the high level of dimensional precision of the tooling, the repeatability of the holes for the mechanical bondig of the seal, measuring a few millimetres, could be guaranteed.

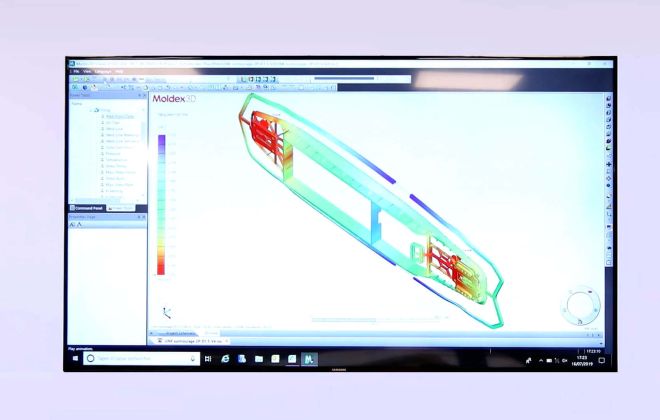

The breakaway area presented a difficulty because the thickness of the material had to be sufficient to obtain a proper filling, but thin enough to allow a clean cut by screwing a cable gland. A rheological study was therefore carried out beforehand. The injection of a rib with a progressive thickness allowed a mechanical grip of the cable gland leading to a clear separation of the zone.

- Rheological study

- Rotating baseplate tooling and bi-material injection

- UL certified material

- 150 t injection moulding machine